See This Report about Sheroz Earthworks

See This Report about Sheroz Earthworks

Blog Article

Facts About Sheroz Earthworks Uncovered

Table of ContentsFacts About Sheroz Earthworks RevealedAn Unbiased View of Sheroz EarthworksSome Known Factual Statements About Sheroz Earthworks Sheroz Earthworks Things To Know Before You BuyThe 2-Minute Rule for Sheroz Earthworks

For any type of earthwork professional, it is crucial to perform job with quality, precision, and on time. Making use of maker control in job machines allows optimizing the different phases in the earthwork process, from preparing to the maintenance stage - trimble parts. The machine control system aids the machine driver in attaining the target plane rapidly and easily

The machine control system guides the operator with centimeter precision. With Xsite PRO 3D, you'll always know exactly just how much to reduce or fill up. Your neighborhood Xsite technical assistance can assist you and aid with any troubles without visiting the website. Remote assistance saves money and time, as it reduces downtime in jobsites.

Top Guidelines Of Sheroz Earthworks

Added training and directions are constantly readily available over remote support when needed. The earthmoving market has utilized our field-proven options because the early 1990s. Our system's parts are carefully created to stand up to the harsh problems of building and construction websites. Comparison of the same job implemented using device control versus the conventional technique exposes that, on standard, the conventional approach calls for 50% even more time to achieve the exact same task as the technology-assisted technique. https://www.40billion.com/profile/569487114.

Go into the Xsite device control system; it's below to provide you with a significant benefit when working with earthmoving equipment. Discover exactly how Xsite Equipment Control can improve your productivity and ensure job safety! Xsite Maker Control systems can be set up to any kind of excavator from mini excavators to big mining excavators.

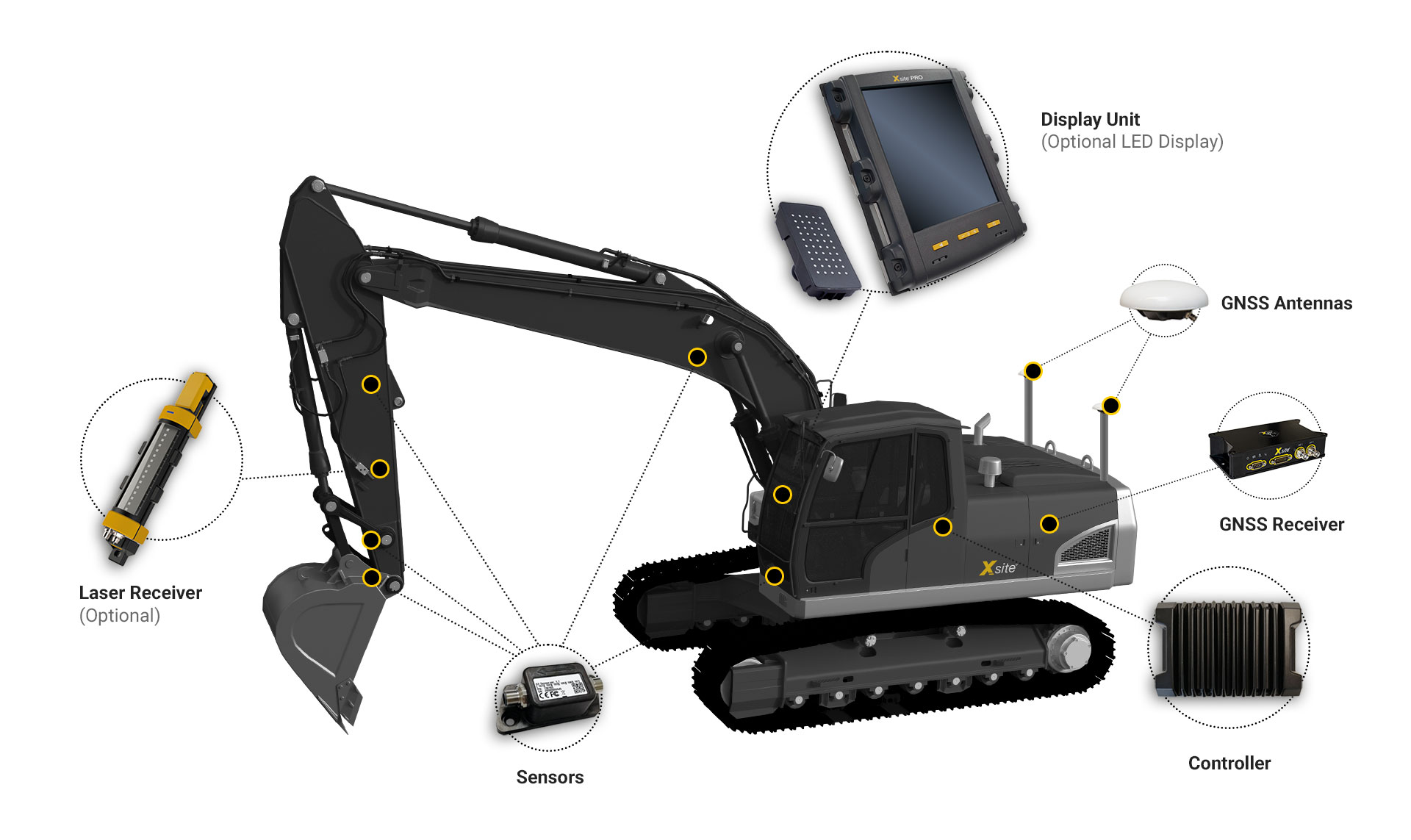

How does machine control job? In 2D systems, the device is equipped with adjusted disposition sensors. These sensing units are placed on the pre-determined parts of the equipment in excavators the sensor are normally mounted to the framework, boom (or booms), digger arm and to the fast coupler - topcon gps. By using the data obtained from these sensors the system can determine the exact placement of the excavators bucket idea in significance to a reference factor.

The system is very easy to find out the basics can be shown in under one hour of training. Just how does the remote support job? A cordless internet link makes it possible to develop a remote link in between the equipment control system and the solution.

The Only Guide for Sheroz Earthworks

Xsite Maker Control systems sustain open typical data styles, allowing seamless details flow from one system to an additional. Depending on your choice of system (with or without placing, i.e., 2D or 3D), your device is outfitted with disposition sensors, a controller device, and a display/operating panel.

Several hardware and software program services exist to aid determine a maker's existing position on the earth and contrast it with a desired layout surfaceand construction operators can do even more to leverage the advantages. Maker control is making use of numerous placing sensing units and a screen to provide the driver with a recommendation in between the placement of the bucket or blade and the target grade.

Relying on the arrangement, maker control systems can give the driver with a basic aesthetic overview to pail or blade setting, or can instantly relocate the blade to grade by speaking with the machine's hydraulics - https://www.artstation.com/floydoverbeck1/profile. There are equipment control systems available for practically any device: , dozers, excavators, dirt and asphalt compactors, scrapes, leaners, grating devices, and pavers

Sheroz Earthworks Can Be Fun For Anyone

Equipment control can also aid increase performance and lower overall prices. Building tools without maker control will certainly become a thing of the past and the advantages acquired from it will be countless.

Trimble equipment control systems supply a myriad of advantages to any individual who uses earthwork equipment and, at EarthCalc, we can provide you with 3D apply for your equipment control-enable tools. Not exactly sure if equipment control deserves the price? Take into consideration the complying with reasons why you need to consider this option.

Making use of GPS lined up with your 3D style documents, these systems virtually guarantee that you will certainly remove or place the proper quantity of material at the building website. On most building and construction websites, revamp is a common and irritating fact, however with Trimble equipment control, you can eliminate the requirement for rework.

See This Report about Sheroz Earthworks

Often, with Trimble device control, you can get rid of excess tools at a details job website. A job that could have required the use of 3 or 4 pieces of digging deep into equipment currently may require only 2 have a peek at this site pieces of tools to achieve the exact same task in much less time. This enables you to relocate your equipment to another job site and deal with numerous jobs at once.

Report this page